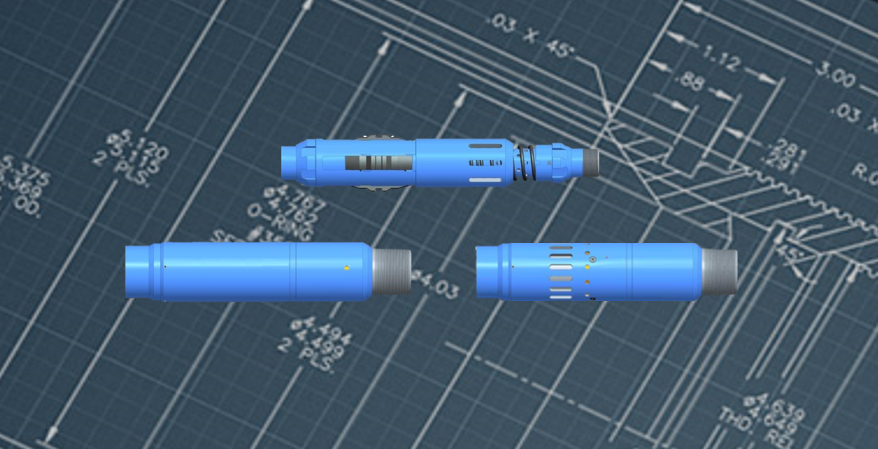

ContactPRO™ Open Hole Ball Drop Fracturing Systems

Liner Top Packer Setting Tool

Liner Top Packer and Latch Seal Assembly

Open Hole Anchor

Open Hole Packer

Re-closable Millable Ball Valve

Millable Ball Valve (Permanent Locked Open)

Pressure Actuated Valve

Absolute Pressure Actuated Toe Valve

Liner Closing Valve

ContactPRO™ CEM Cemented Ball Drop Fracturing Systems

Millable Ball Valve (Permanent Locked Open)

Absolute Pressure Actuated Toe Valve

Liner Closing Valve

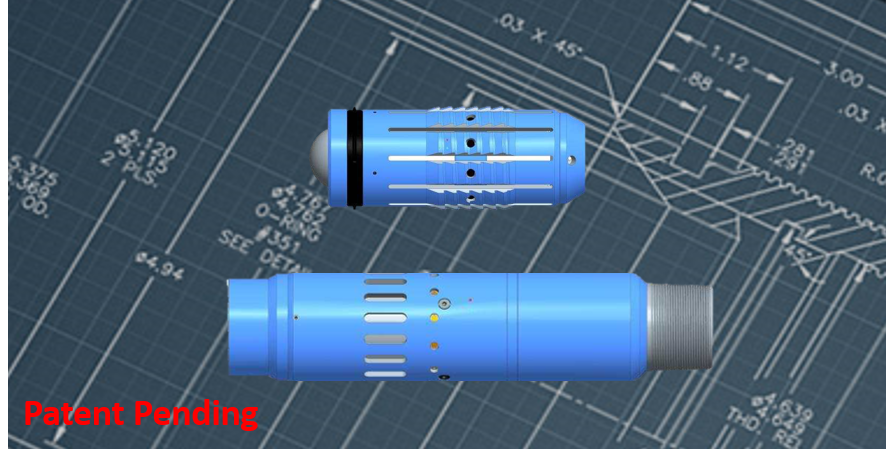

Open Hole Packer

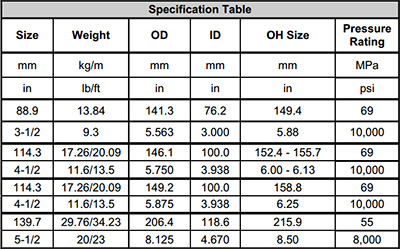

ACTS Open Hole Packer is a hydraulically actuated packer which provides proven isolation between open hole fracturing intervals. The compact design reduces friction associated with bending and results in reliable deployment through aggressive build sections in the wellbore. The packer’s short length and minimal weight also eliminates any requirements for handling pup joints further reducing operator costs. The packer incorporates a specially designed element anti-extrusion back-up ring system differentially rated up to 69 MPa (10,000 psi) resulting in reliable isolation in a wide range of open hole conditions. The packer’s ID enables future milling and service tools to easily pass through without any restriction concerns. The packer is available in multiple thread and metallurgy configurations to be equivalent to required liner specifications for varying downhole operating environments.

Features & Benefits

- 69 MPa (10,000 psi) differentially rated for high pressure fracturing operations

- All packer elastomers rated to 204 °C (400 °F) for high temperature wellbore applications

- Packer design incorporates additional stroke and OD expansion capabilities to isolate enlarged open hole sections

- Trigger pressure is adjustable to accommodate varying operating requirements

- Internal hydraulic chamber ratchet ring ensures element packoff is maintained or enhanced during fracturing or production operations

- Top and bottom subs of packer are designed to ensure packer’s setting force is not lost due to cylinder sliding friction

- Premium threads and metallurgies available for various wellbore environments