ContactPRO™ Open Hole Ball Drop Fracturing Systems

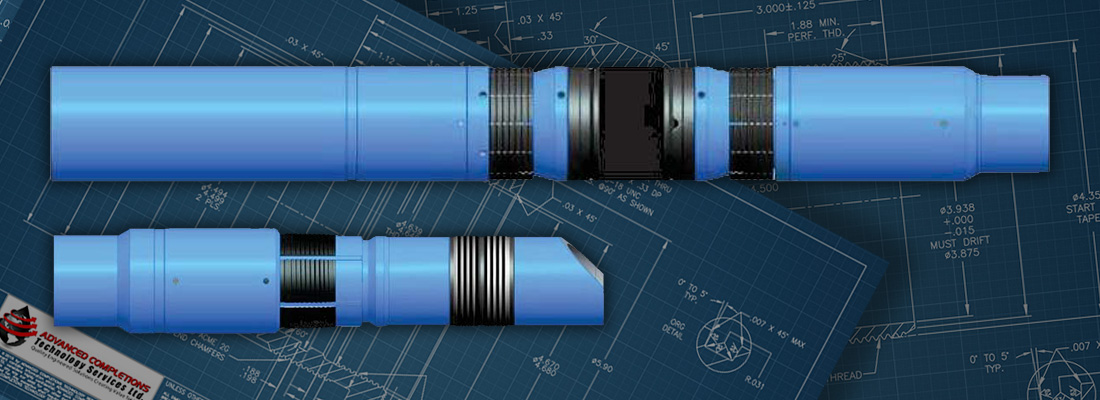

Liner Top Packer Setting Tool

Liner Top Packer and Latch Seal Assembly

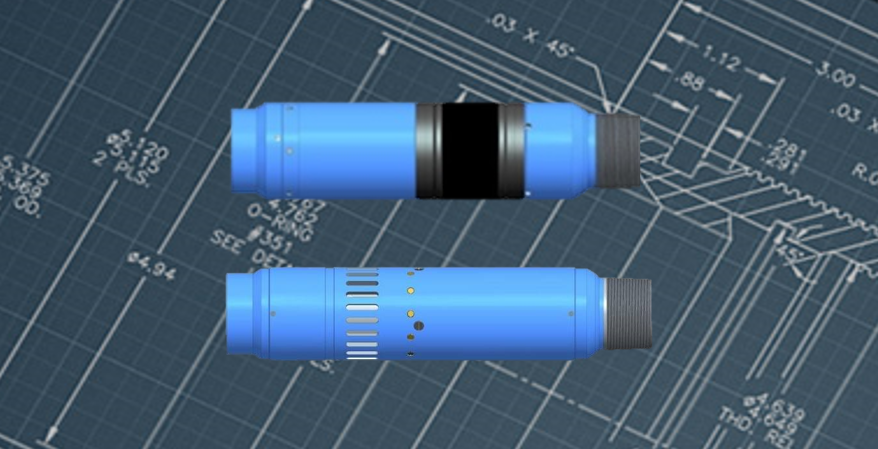

Open Hole Anchor

Open Hole Packer

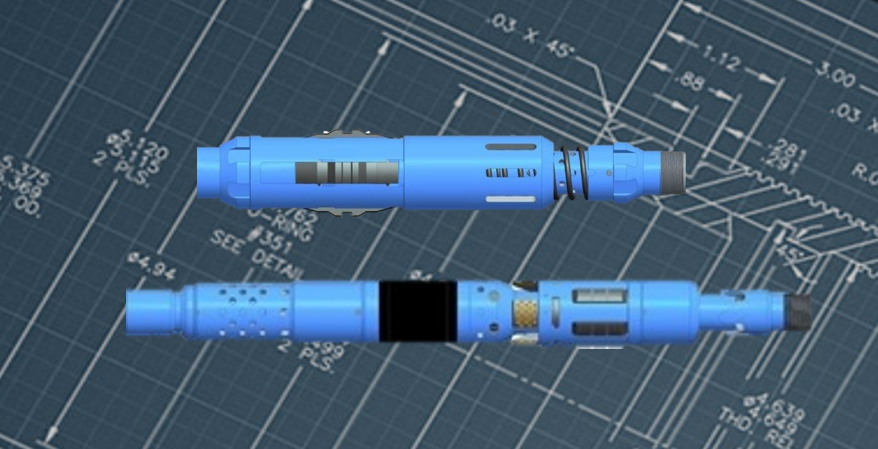

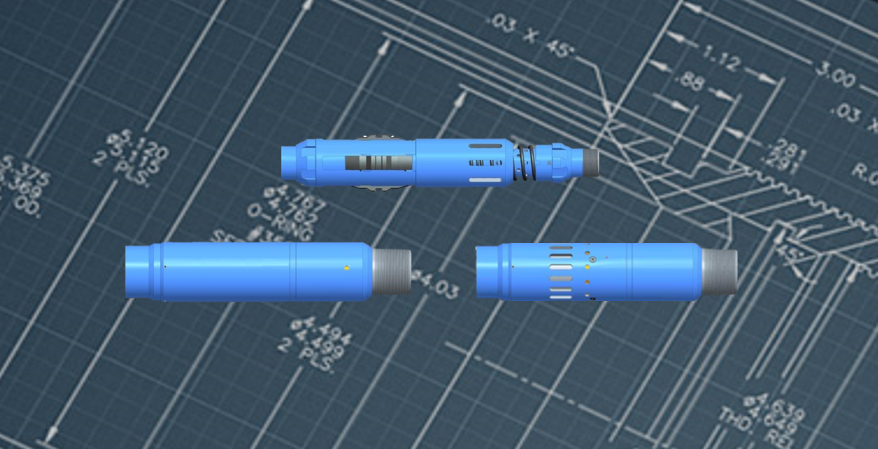

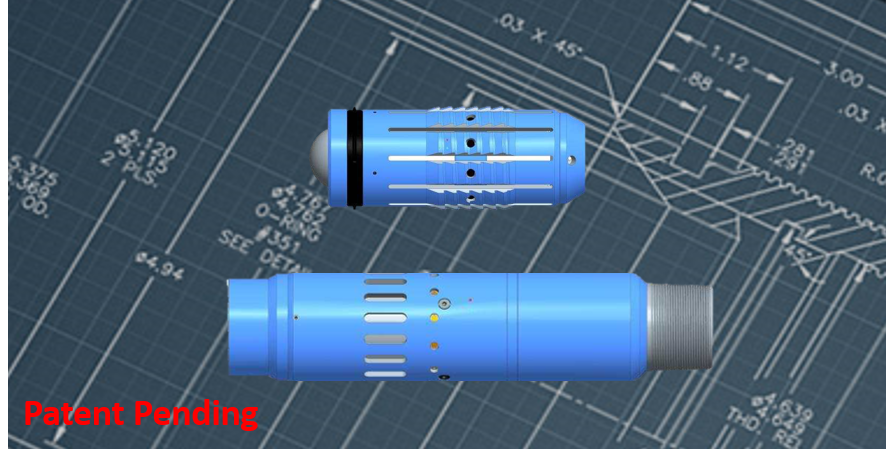

Re-closable Millable Ball Valve

Millable Ball Valve (Permanent Locked Open)

Pressure Actuated Valve

Absolute Pressure Actuated Toe Valve

Liner Closing Valve

ContactPRO™ CEM Cemented Ball Drop Fracturing Systems

Millable Ball Valve (Permanent Locked Open)

Absolute Pressure Actuated Toe Valve

Liner Closing Valve

Liner Top Packer and Latch Seal Assembly

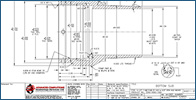

ACTS Liner Top Packer is a hydraulically actuated packer that hangs the liner string in the casing, provides isolation in the intermediate casing, and acts as an anchored receptacle for drilling, fracturing, and production strings. ACTS Latch Seal Assembly effectively anchors and seals into the liner top packer’s receptacle providing flexibility for changing tubing strings to surface. Both equipment designs are compact and reduce friction associated with bending preventing premature setting which results in reliable deployment through aggressive build sections in the wellbore. The packer is proven to effectively function in diverse casing weight ranges and incorporates a specially designed element antiextrusion back-up ring system differentially rated to 69 MPa (10,000 psi) resulting in reliable isolation. The latch seal assembly incorporates a free point feature that enables effective tubing string disconnection from the liner top packer even in highly deviated build sections. The packer and latch seal assembly are available in multiple thread and metallurgy configurations to be equivalent to required liner specifications for varying downhole operating environments.

Features & Benefits

- 69 MPa (10,000 psi) differentially rated for high pressure fracturing operations

- Packer’s trigger pressure is adjustable to accommodate varying operating requirements

- Internal hydraulic chamber ratchet ring ensures element packoff is maintained or enhanced during fracturing or production operations

- Bi-directional slip design protected from impact to prevent pre-sets

- Latch seal assembly’s free point detection feature promotes reliable tubing string disconnection from packer

- Can be selectively set with optional ball drop setting tool providing operational flexibility

- Premium threads and metallurgies available for various wellbore environments