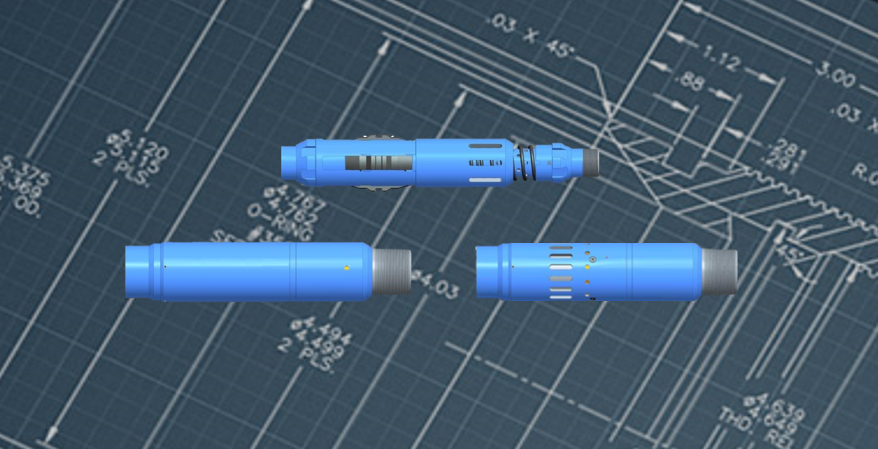

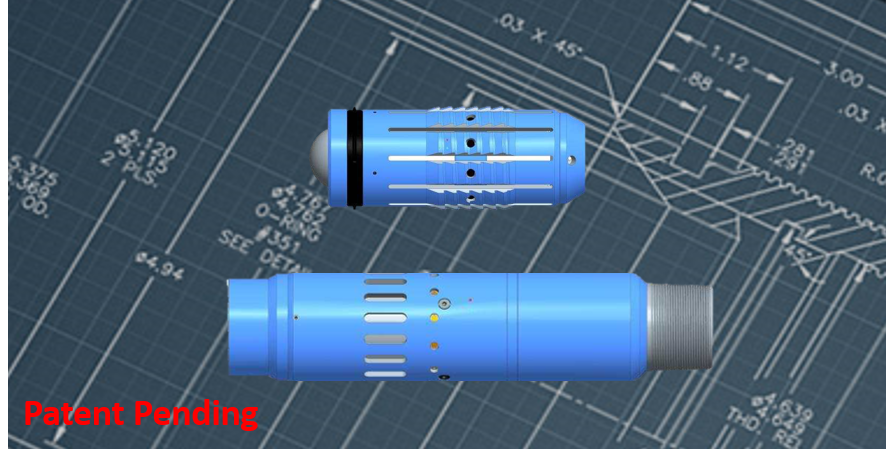

VantagePRO™ Cemented Shiftable Valve & Coil Systems

Permanent Lock Cemented Shiftable Valve

Re-closable Cemented Shiftable Valve – SVS

Re-closable Cemented Shiftable Valve – DVS

Liner Closing Valve

Cemented Pressure Actuated Toe Valve

Coiled Tubing BHA Components

Resettable Compression Packer

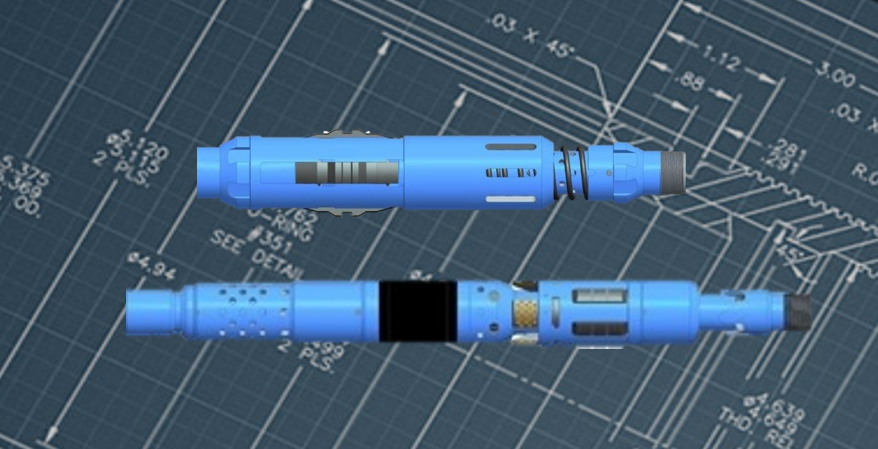

Abrasive Perforator

Cemented Shiftable Valve Actuating Tool

Casing Collar Locator

Reverse Unloader

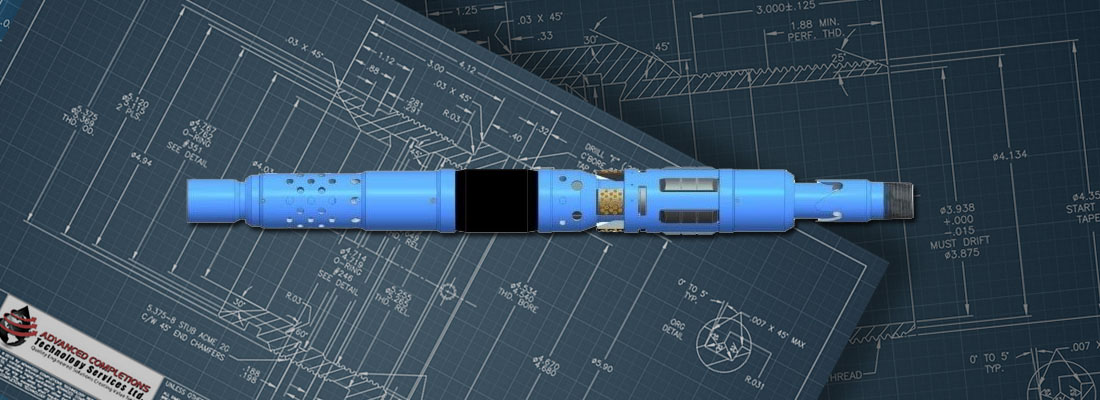

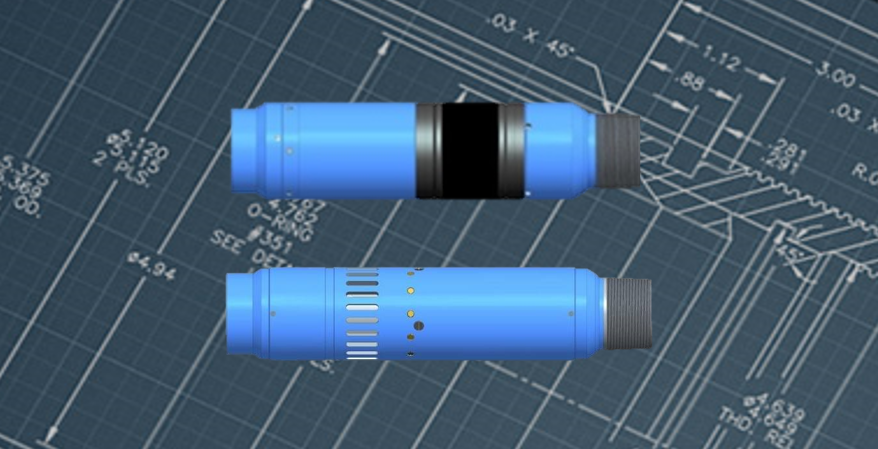

Resettable Compression Packer

ACTS Resettable Compression Packer is a mechanical actuated, single grip, multi-set compression packer designed to provide cased hole interval isolation. The packer is usually run in tandem with ACTS Abrasive Jet Perforator which cuts multiple perforations into the liner while the packer acts as the isolation device during cutting and stimulation operations. The packer can be run on jointed tubing, but for efficiency advantages is typically run on coiled tubing. A unique proppant and debris-tolerant continuous jay and lug ring design functions the packer when the tubing is reciprocated up and down. These features along with the packer’s integral unloader system and sealing element technology permit the packer to be reliably run, set, and released multiple times in the wellbore. The packer can also be easily converted to ACTS Straddle Packer by adding an upper cup assembly and be utilized for liner pressure testing operations.

Features & Benefits

- Proppant and debris-tolerant continuous jay and lug ring design permits packer to function reliably in severe operating conditions

- Debris-tolerant integral unloader valve allows for differential pressure release prior to unsetting the packer’s sealing element enabling easy release

- Sealing element technology prolongs element integrity and enables minimal pack-off force to set packer in extended reach horizontal wellbore applications

- Durable carbide slips promote aggressive packer anchoring ability to the liner in proppant-laden conditions

- Packer can be run with an optional check valve to enable circulating operations down the annulus and up the coil prior to packer release

- Compatible with other ACTS Cased Hole Coiled Tubing Fracturing System equipment providing flexibility for multiple wellbore applications

- Available in 41 or 69 MPa (6,000 or 10,000 psi) differential pressure