VantagePRO™ Cemented Shiftable Valve & Coil Systems

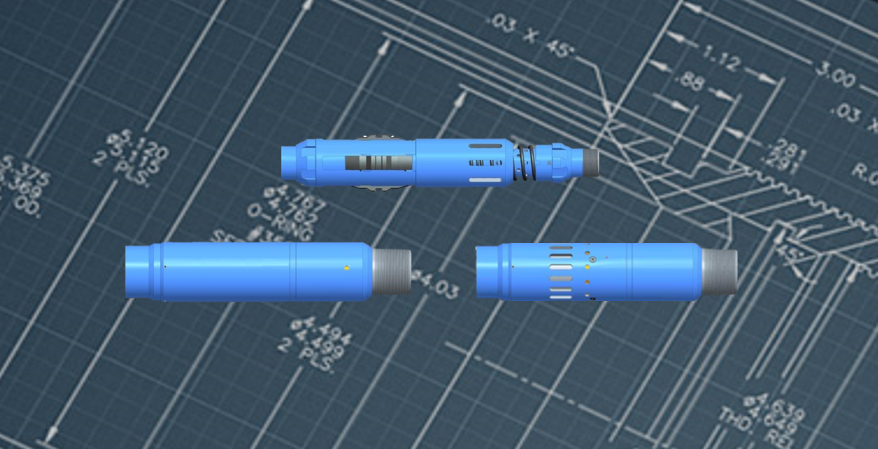

Permanent Lock Cemented Shiftable Valve

Re-closable Cemented Shiftable Valve – SVS

Re-closable Cemented Shiftable Valve – DVS

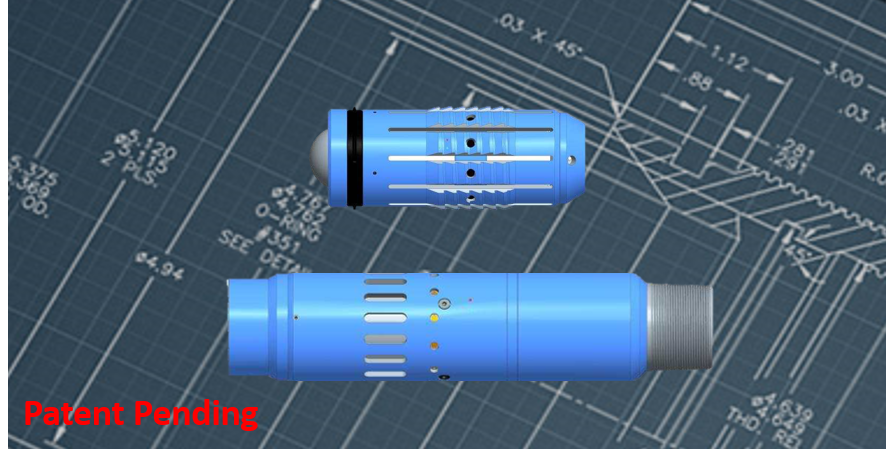

Liner Closing Valve

Cemented Pressure Actuated Toe Valve

Coiled Tubing BHA Components

Resettable Compression Packer

Abrasive Perforator

Cemented Shiftable Valve Actuating Tool

Casing Collar Locator

Reverse Unloader

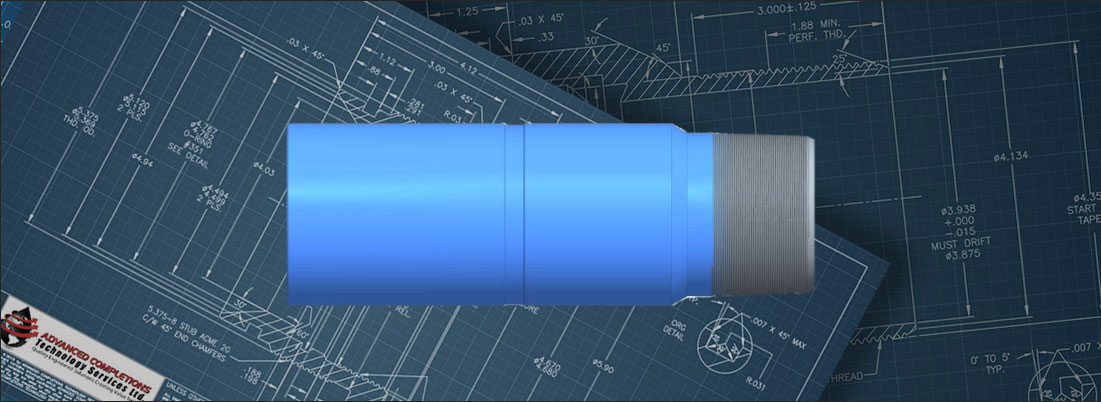

Liner Closing Valve

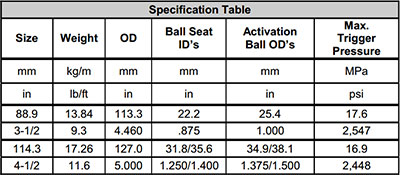

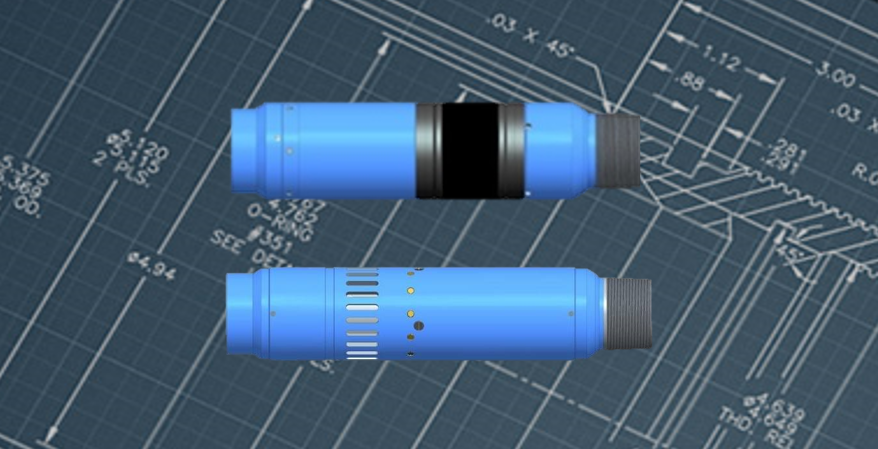

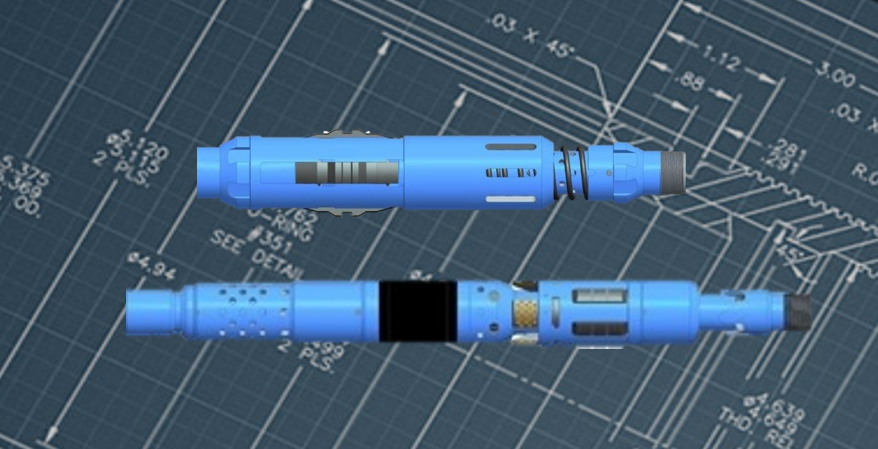

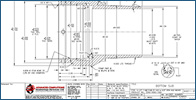

ACTS Liner Closing Valve is a hydraulically actuated isolation valve designed to close the lowermost (toe) end of the liner once circulation operations are completed after liner installation. When the valve closes, the remaining hydraulic actuated equipment along the liner can then be functioned. The valve is closed by circulating a fixed diameter activation ball (open hole completions) or a collapsible wiper ball (cased hole completions) to the valve’s ball seat. Once the ball lands on the seat, pressure is applied from surface until a predetermined valve actuation pressure is achieved. An internal piston then shifts down and locks the valve closed which permanently closes the liner for additional pressuring operations. Large internal flow geometries have been incorporated into the valve to accommodate faster circulation rates and to prevent plugging. The valve is available in multiple thread and metallurgy configurations to be equivalent to required liner specifications for varying downhole operating environments.

Features & Benefits

- Available with two ball seat ID and activation ball diameter options for regular and high flow circulation operations

- Trigger pressure is adjustable to accommodate varying operating requirements

- Once actuated, the valve permanently locks closed providing a reliable liner seal

- Internal seat geometries designed to accept a fixed diameter activation ball for open hole completions or a collapsible wiper ball for cased hole completions

- Premium threads and metallurgies available for harsh wellbore environments