VantagePRO™ Cemented Shiftable Valve & Coil Systems

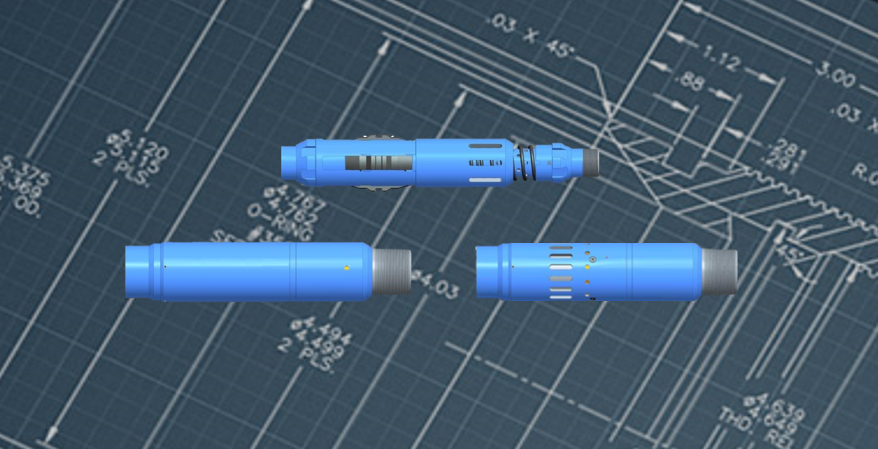

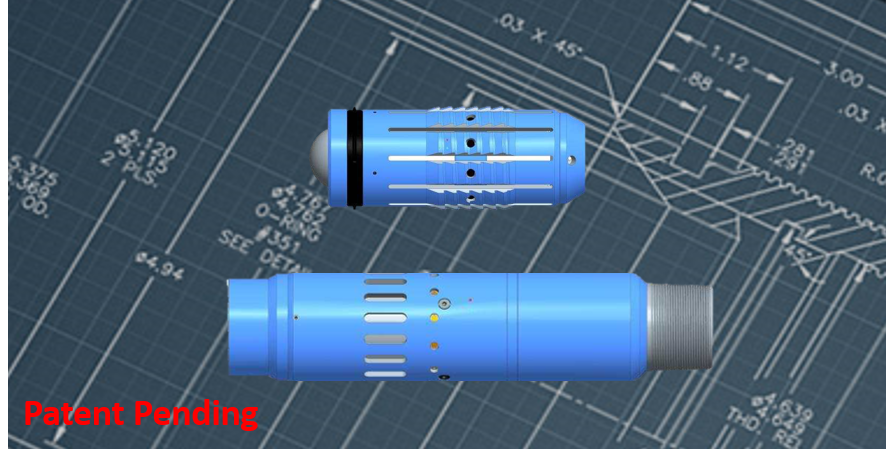

Permanent Lock Cemented Shiftable Valve

Re-closable Cemented Shiftable Valve – SVS

Re-closable Cemented Shiftable Valve – DVS

Liner Closing Valve

Cemented Pressure Actuated Toe Valve

Coiled Tubing BHA Components

Resettable Compression Packer

Abrasive Perforator

Cemented Shiftable Valve Actuating Tool

Casing Collar Locator

Reverse Unloader

Abrasive Jet Perforator

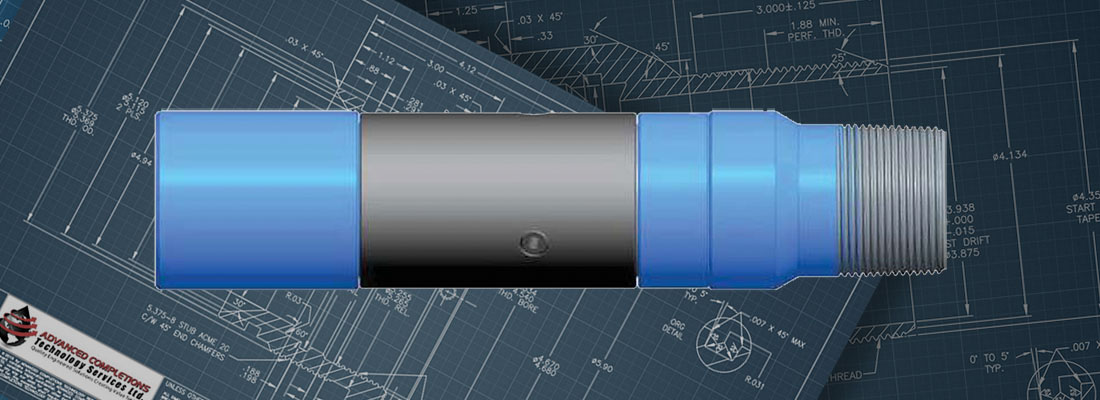

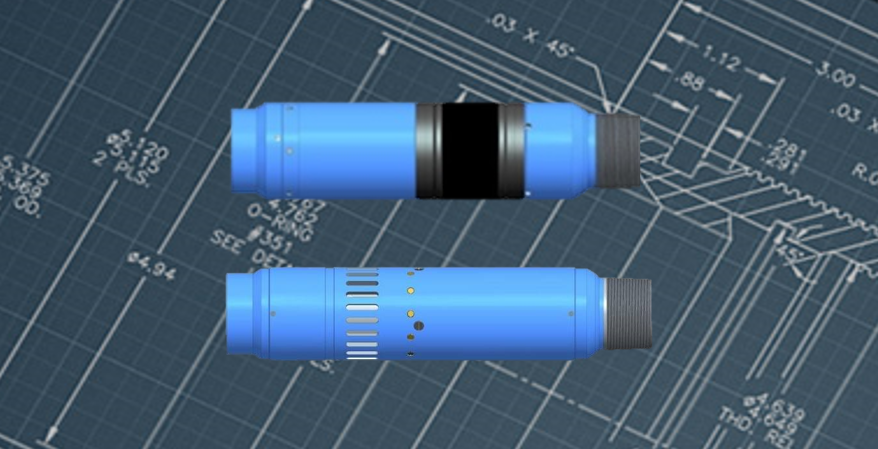

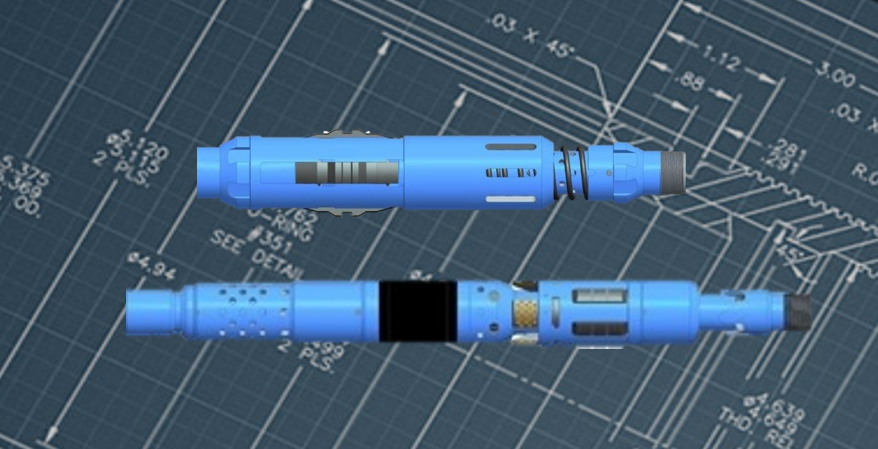

ACTS Abrasive Perforator is a cutting tool run on coiled tubing used to create multiple perforations in the liner providing wellbore access to the formation. Fluid (with proppant) is pumped through the tool and accelerates through the radial jetting nozzles creating high velocity streams that cut through the steel liner and penetrate into the formation. This creates a communicative entry point for pressurized fluid to enter the reservoir during stimulation operations. The perforator’s nozzle’s and outside protection sleeve are comprised of carbide to prevent premature wear while jetting action occurs. The perforator is usually run in tandem with ACTS Resettable Compression Packer which acts as the isolation device during cutting and stimulation operations

Features & Benefits

- 3 120° phase erosion resistant carbide nozzles maintain their internal diameters throughout abrasive perforating operations providing consistent cuts in 5-10 minutes with minimal fluid pumping rates

- Carbide nozzles with different internal diameters are available to suit different cutting fluid rates and cutting proppant size requirements

- External carbide protection sleeve ensures perforator outside diameter erosion does not occur during cutting operations maintaining tool integrity

- Abrasive perforator is used to “fluidize” area above ACTS Resettable Compression Packer after screen-outs enabling circulation to be reestablished and packer to be reliably released

- Simple and efficient design allows for easy nozzle re-dress in the field if

required