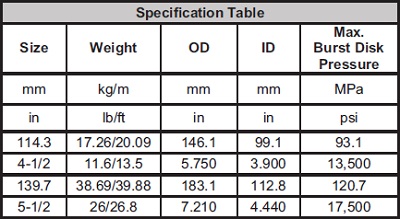

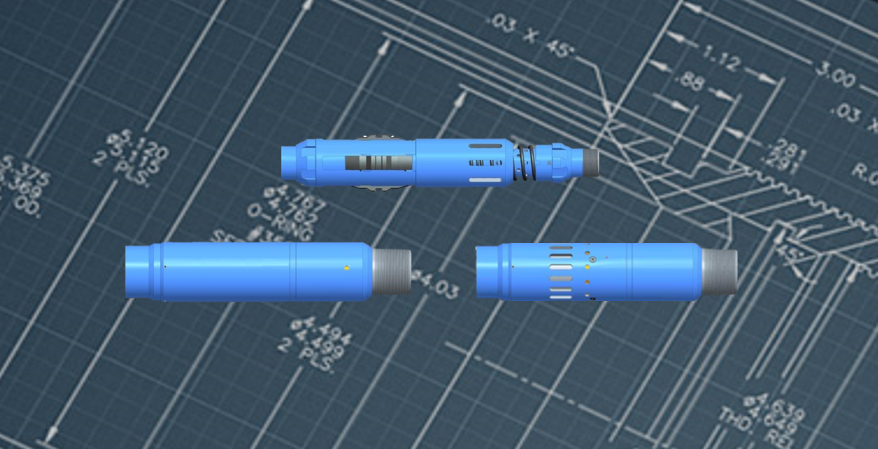

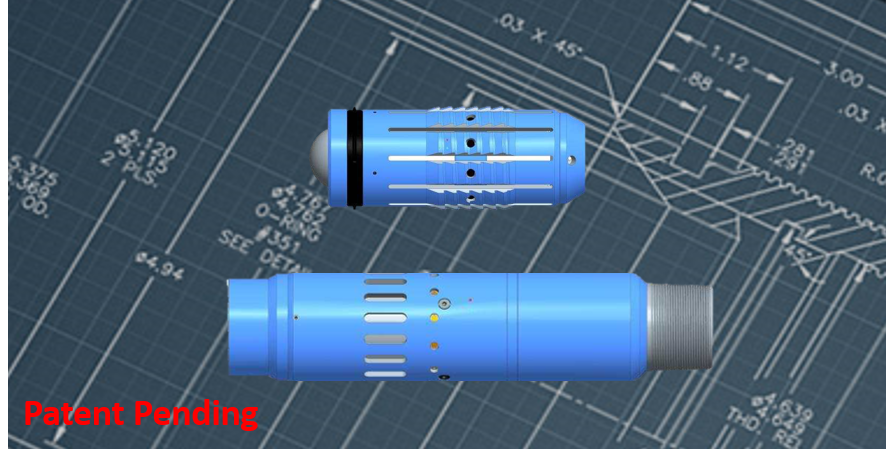

Cemented Pressure Actuated Valve

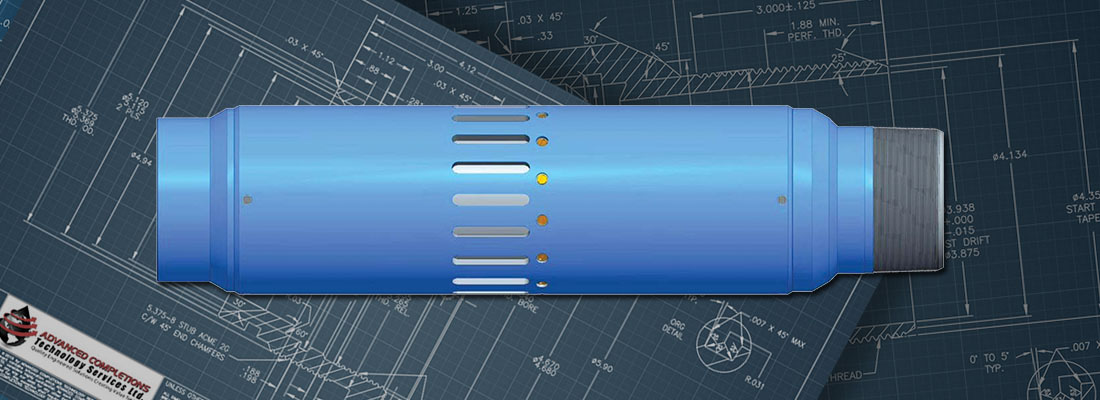

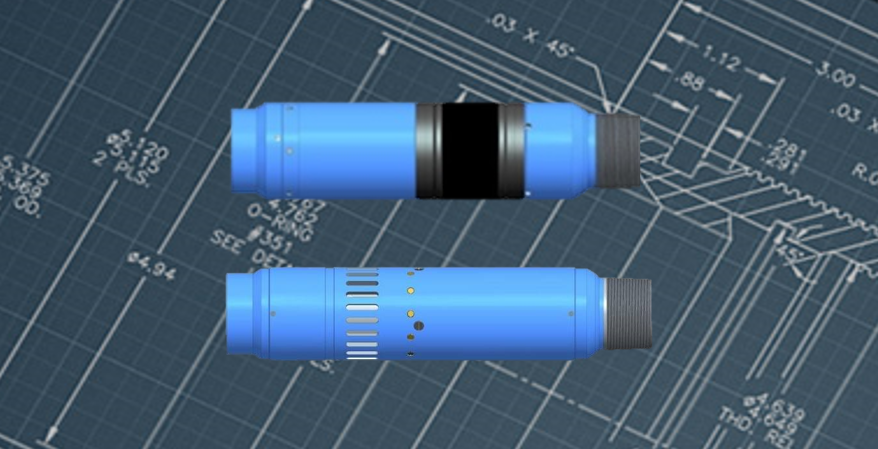

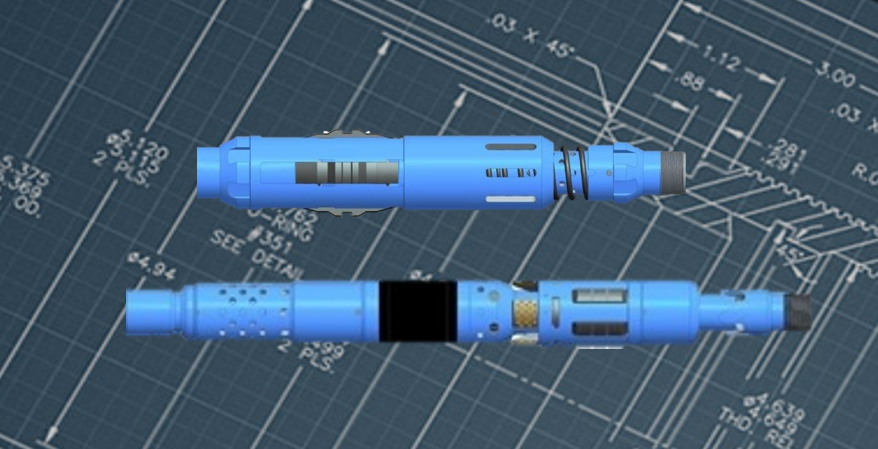

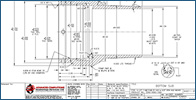

ACTS Cemented Pressure Actuated Valve is a hydraulically actuated fracturing valve designed for liner integrity testing operations prior to initiating fracturing operations at the lowermost (toe) interval. The valve’s internal components have been specifically engineered and field proven to function reliably after cased hole cementing operations eliminating any concerns of valve lock-up. After the liner is successfully pressure tested, applied pressure is increased to a predetermined valve actuation pressure. A burst disc located in the valve ruptures and pressure acts against the valve’s piston to open the valve. An internally contained spring acting against the piston ensures the valve fully shifts and locks open. Once opened, high flow circumferential ports, permit continuous communication to the reservoir for high pressure stimulation operations and production. The valve is available in multiple thread and metallurgy configurations to be equivalent to required liner specifications for varying downhole operating environments.

Features & Benefits

- Multiple burst discs installed in the valve for operational redundancy

- Burst discs available in 3.5 MPa (500 psi) increments with specific operating temperature values

- Full drift ID ensures effective passage of standard cement wiper plugs

- Spring assisted piston ensures valve fully opens and locks open

- Valve port area is larger than liner flow area to prevent stimulation screenouts at the valve

- Operating components are physically protected from internal and external manipulation

- Premium threads and metallurgies available for harsh wellbore environments